Cincinnati, Ohio, like much of its brethren across the United States is in the midst of trying to remedy decades of sanitary sewer and combined sewer overflows and maintain its aging underground sewer infrastructure, much of which was built in the late 1800s or early 1900s.

At the helm making sure the system is operating in top form and working through the federally mandated consent decree is the Metropolitan Sewer District of Greater Cincinnati (MSDGC). The publically operated wastewater utility serves 43 of 49 political subdivisions in Hamilton County, as well as parts of Butler, Clermont and Warren counties. The more than 290-sq-mile service area has approximately 3,000 miles of sanitary and combined sewers, serving approximately 230,000 residential and commercial ratepayers.

“I can’t speak to the clean water side of things, but the sewer system, like most systems around the country, is in need of a significant influx of resources to bring it up to an ideal condition,” says Michael Stevens, P.E., Wastewater Collection. “Many sewers are showing their age and will need rehabbed, repaired or replaced in a relatively short time frame. There are combined sewers around the County that lack adequate capacity during storms to prevent sewer back up into buildings or overflow into streams.”

A common refrain among utility owners across the country is that funding to fix these infrastructure issues is not there.

To help prioritize where the greatest needs lie, MSDGC has aggressively pursued a robust risk-based asset management strategy that combines its GIS, computerized maintenance management system, risk and condition assessment data, to predict what work needs to be done and where.

“While this strategy is in its relative infancy and has not yet been adopted at all levels, I’m confident that it is a leap in the right direction and will guide our limited resources to where they’re needed most,” Stevens says.

The Multi-Phase Plan

Also guiding the way is the consent decree that MSDGC has worked on with the U.S. EPA and the state since 1997. Despite this late 1990s start date, MSDGC realized long before that, that components in its system were reaching the end of its useful life. According to the district’s Project Groundwork website, since the mid-1990s, more than 40 overflow points in the system were eliminated. Project Groundwork is the name given to the projects mandated by the consent decree, and like many consent decree projects across the country, the work is ripe for trenchless applications.

Project Groundwork, is referred to as the largest public works project in Hamilton County’s 200-plus year history, and focuses on:

• Reducing or eliminating sewage overflows into local rivers and streams and sewage backups into basements.

• Benefiting Hamilton County communities through environmentally, socially, and economically sustainable solutions to these current problems; and

• Revitalizing the economy through creation of jobs and growth opportunities for local businesses.

Project Groundwork is broken into two phases. Phase 1, from 2009 to 2018, is estimated to cost $1.145 billion (in 2006 dollars) and includes construction of 115 projects and design of 62 additional projects by Dec. 30, 2018. Phase 2, after 2018, is estimated to cost $2.1 billion (in 2006 dollars) and is slated to include approximately 256 projects across the county.

The MSDGC’s proposed capital improvement budget for 2016 notes that 82, of 109, consent decree Phase 1 milestones have been reached. The $331 million proposed budget for 2016 includes 90 capital improvement projects. Sixty-two percent of those funds are for Wet Weather Improvement Program projects that were listed in the final consent decree. According to the budget documents, the Phase 1 Wet Weather Program is on schedule and on budget in accordance with the final consent decree.

In 2016, the district is planning to replace approximately 5,200 ft of aging/deteriorated sanitary sewers, 5,000 ft of aging/deteriorated combined sewers and lining approximately 1,100 ft of aging/deteriorated sewers. It also calls for the construction of 35,600 ft of new sanitary sewers, 8,100 ft of new combined sewers and 30,100 ft of new storm sewers.

Overseeing the construction work at the district are two divisions, Wastewater Collection, which handles the district’s relining work, and Wastewater Engineering, which handles the larger capital improvement and replacement projects. A separate department within the City, Greater Cincinnati Water Works, handles the clean water system.

Though both MSDGC divisions perform cured-in-place pipe (CIPP) projects, the amount of CIPP work the engineering side performs is limited. The Wastewater Collection Division, under an annual funding allowance, performs most of the CIPP and lateral work.

Wastewater Collections

Like many sewer districts across the country, CIPP is not new to Cincinnati. According to Stevens’ research, the earliest lining project took place in June 1983. Though he does not have details on that project, the same sewer was CCTV’d in 2002 and no defects were reported. Since 1983, MSDGC has lined more than 1 million ft of sewer, spending an average of $6 million a year on CIPP work.

“The annual trenchless allowance allows for CIPP lining of 10 to 12 miles of sewer per year ranging in diameter from 8 to 54 in.,” says Stevens. “Over 54 in., we start looking at alternate forms of rehab such as spray-applied cementitious coatings.”

Using a variety of condition assessment methods, the district developed a comprehensive risk model for all 98,000 gravity sewers in the service area. The risk level takes into consideration the likelihood and consequence of the failure both from a structural and maintenance perspective.

As the district completes condition assessment inspections on each of its gravity sewers, the structural likelihood of failure is updated. The frequency of maintenance work performed on an asset is the primary driver in determining the maintenance risk. At this point, nearly half of the MSDGC’s gravity sewer system has been inspected and coded per the NASSCO PACP standards.

“The fact that an asset is high risk does not necessitate any specific work to be performed on said asset. For this reason, we use Innovyze’s GIS-based Infomaster software to develop recommended rehab methods for each of our segments,” says Randy Schneider, P.E., Wastewater Collection. “These recommended methods include actions anywhere from monitor — for future maintenance — to repair/replacement and full lining.”

Schneider continues, “Based on the aforementioned risk of the assets, we set a date that the recommended action is to take place. We use this information for budget forecasting in each of our funding categories, both capital and operations and maintenance. The intent is to ensure we have adequate funding to perform just-in-time renewal and maintenance on each of our assets.”

The district has developed a risk model for its 74 miles of pressurized mains, as well, and it is in the process of developing best maintenance practices based on this risk model.

“CIPP lining has proven itself to be a cost-effective alternative to traditional excavation repairs and as pricing continues to drop, newer technologies such as UV-cured glass reinforced plastic CIPP will be adopted by more municipalities,” Stevens’ says. “MSDGC is proposing to use all UV-cured GRP CIPP on our next annual contract for 2016. While standard felt/resin CIPP has been a tremendous success for us here, we have struggled with styrene odor migration during installation, resulting in some serious situations over the past five years. UV-cured CIPP includes an inner and outer layer that is impervious to airborne styrene. In addition, the light-curing process does not introduce the primary mechanism of pressurized steam by which styrene odors migrate through the pipe and building connections.”

“CIPP lining has proven itself to be a cost-effective alternative to traditional excavation repairs and as pricing continues to drop, newer technologies such as UV-cured glass reinforced plastic CIPP will be adopted by more municipalities,” Stevens’ says. “MSDGC is proposing to use all UV-cured GRP CIPP on our next annual contract for 2016. While standard felt/resin CIPP has been a tremendous success for us here, we have struggled with styrene odor migration during installation, resulting in some serious situations over the past five years. UV-cured CIPP includes an inner and outer layer that is impervious to airborne styrene. In addition, the light-curing process does not introduce the primary mechanism of pressurized steam by which styrene odors migrate through the pipe and building connections.”

Gaining more traction in the relining side of the trenchless industry is lateral work. Many industry insiders see this as one of the emerging segments and Cincinnati is no different. Like other utility owners, the sticky wicket is the private property issue of laterals – or as listed in the district’s rules and regulations as “building sewers.”

Until 2010, the district had no way of creating a maintenance or condition assessment schedule set for building sewers because they are private assets resulting in most of the repair work being done on a reactive (more costly) basis. Through a partnership with Duke Energy, MSDGC began televising all sewer related assets in areas where new gas lines are installed.

“The partnership jumpstarted the district’s efforts to perform condition assessment and obtain GIS level location information on building sewers,” Schneider says. “Using this location and condition information, MSDGC is able to identify building sewers to be ‘renewed’ via trenchless technologies.”

Since the start of its lateral renewal program in 2012, the district has installed more than 1,500 lateral liners. The district uses LMK Technologies VAC-A-TEE system to install cleanouts and then install a lateral liner, using LMK products. Schneider says MSDGC can install the VAC-A-TEE and lateral liner for about one-tenth of the cost of reactively repairing a building sewer via trench excavation.

Wastewater Engineering

Of course, not everything can be installed using a “totally” trenchless method and handling those projects is Wastewater Engineering.

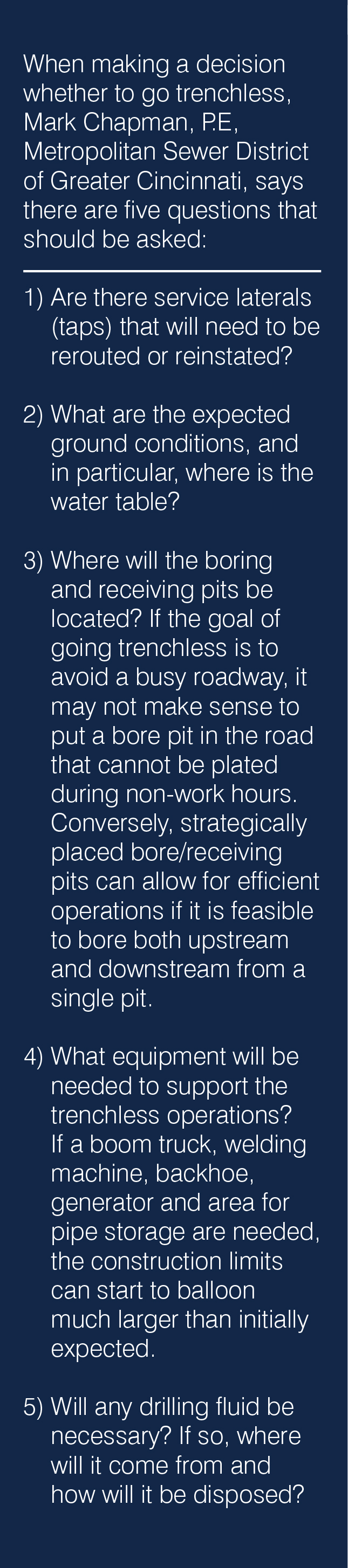

Traditional cut-and-cover is the default solution for many projects, but MSDGC Wastewater Engineering keeps an open mind to trenchless methods for more difficult projects, says Mark Chapman, P.E., Wastewater Engineering.

Looking at the data, Chapman estimates that the district has used modern trenchless methods — most commonly jack-and-bore — for at least 35 years, but he noted that many of the large-diameter sewers were installed using hand tunnelling, like the Auxiliary Mill Creek Interceptor that was installed in the 1960s.

According to Chapman, the district has five active trenchless projects. For 2016, the district is still finalizing the design on several projects, and currently looking at five to 10 projects using trenchless, as well. Most of its projects have a combination of both open-cut and trenchless and sometimes that trenchless is as little as 50 to 100 ft.

One recent Project Groundwork-related project, the Oakley Separation Sewer Project, incorporated trenchless and also marked the district’s first use of the design-build contracting method. The project, estimated at $12.2 million, included a half-mile of 60- and 72-in. trenchless storm and near-surface sewer pipes, to separate the storm and sanitary systems for approximately 100 acres of urban property that the City was revitalizing for a theater, retail shopping and an open-style market. Using the design-build method, the project wrapped up 15 months after the notice to proceed and the district saved more than $3.3 million.

The project was named a Trenchless Technology magazine 2014 Project of the Year Honorable Mention for New Installation and recently received the 2015 National Award of Merit for Water/Wastewater from the Design-Build Institute of America. The Oakley project design team relied on expertise from MSDGC, Brown and Caldwell, Ulliman Schutte Construction LLC, IBI Group and Midwest Mole.

“The project was revolutionary for MSDGC, because it proved the proper application of collaborative delivery systems can yield tremendous benefits. The integration between MSDGC and Ulliman Schutte proved to provide the ideal project environment,” says Ali Bahar, principle engineer, Wastewater Engineering. “Collaborative delivery allowed for a fair allocation of project risks and provided the team flexibility to optimize solutions for the differing site conditions encountered. This prestigious award serves as national recognition of the project team’s outstanding collaboration, dedication and professionalism. It serves as proof that the collaborative project delivery model can be successfully utilized on trenchless projects to surpass the expectations of a traditional project delivery model on certain projects.”

In the Toolbox

Both Chapman and Schneider acknowledge the place that trenchless technology holds in a utility owner’s toolbox, especially in light of the deteriorating infrastructure, in heavily conjected and growing urban areas, across the nation.

“Utilities that used to be above ground on poles are in many places now going subterranean. Given this reality, excavation repairs necessarily have a higher risk than in the past. Higher risk equals higher cost,” Stevens says. “Any municipality or contractor that has ever hit a fiber optic cable can tell you that digging can have significant negative consequences. Here at MSDGC, we have lined sewers that would otherwise have been excavated simply because the underground utility density was just too high to dig or because the site-specific conditions prevented equipment access. Employing trenchless technologies meant having a quality, cost-effective alternative process to renew these pipes.”

Though many municipalities and utility owners are aware of the benefits of trenchless, some may shy away from employing them in favor of tried-and-true open-cut.

“Trenchless is certainly an option that every community and its engineers should keep in their toolbox,” Chapman says. “Once you have a handle on the different trenchless methods and weigh the risks/benefits against open-cut construction, it typically becomes obvious which method is best suited for a specific project.”

Read More

Liotti is the 23rd winner of the award and will officially be recognized by his peers at the 2015 NASTT No-Dig Show Kick-Off Breakfast March 16 at the Colorado Convention Center in Denver.

Liotti is the 23rd winner of the award and will officially be recognized by his peers at the 2015 NASTT No-Dig Show Kick-Off Breakfast March 16 at the Colorado Convention Center in Denver.